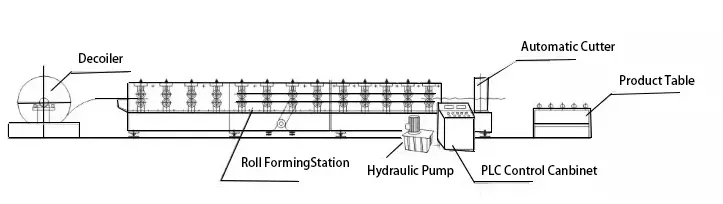

Automatic Storage Rack Roll Forming Machine PLC-Controlled Shelving Production Line

Automatic Storage Rack Roll Forming Machine: 15m/min speed, ±0.5mm precision. Siemens PLC control, Cr12 blades (HRC58-62).CE/ISO-certified.

Automatic Shelving Panel Storage Rack Roll Forming Making Machine Shelf Panel Roll Forming Machine

|

NO.

|

Name

|

QTY

|

Remark

|

|

1

|

5T hydraulic decoiler

|

1 set

|

Max 5T

Max coil:800mm Hydraulic expansion and motorizied decoiling |

|

2

|

Holes Punching & corner cut

|

4 sets

|

We use hydraulic punching machine

Corner cut mould:2 sets ( left and right side can be adjustable manually) Lateral holes punching mould: 1 set( position can be adjustable manually) |

|

3

|

Logo stamping

|

1 set

|

Stamping mould:1 set

|

|

4

|

Roll forming Machine

|

1 set

|

wall panel catilever structure

24 forming stations 15KW motor made in China |

|

5

|

Hydraulic Cutting&bending mould combination

|

1 set

|

Cutting power:7.5kw

Mould material:Cr12.HRC58-62 |

|

6

|

Run-out table

|

2pcs

|

Steel frame with Rollers

|

|

7

|

Electric control panel

|

1 set

|

PLC control system ,Siemens from German brand

Yaskawa inverter from Japan |

|

8

|

Hydraulic system

|

1 set

|

Solenoid is made in China

|

The production line is highly integrated by uncoiling ,leveling,forming,cutting off,punching,receiving and related process. The whole production line is controlled by PCL program .

Details:

|

Suitable Material

|

Galvanized Steel Coil

|

|

Material Width

|

According to Profile Drawing

|

|

Material Thickness

|

0.8-1.2 mm

|

|

Roll forming speed

|

10-15 m/min (Exclude Punching & Cutting Time)

|

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry