Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

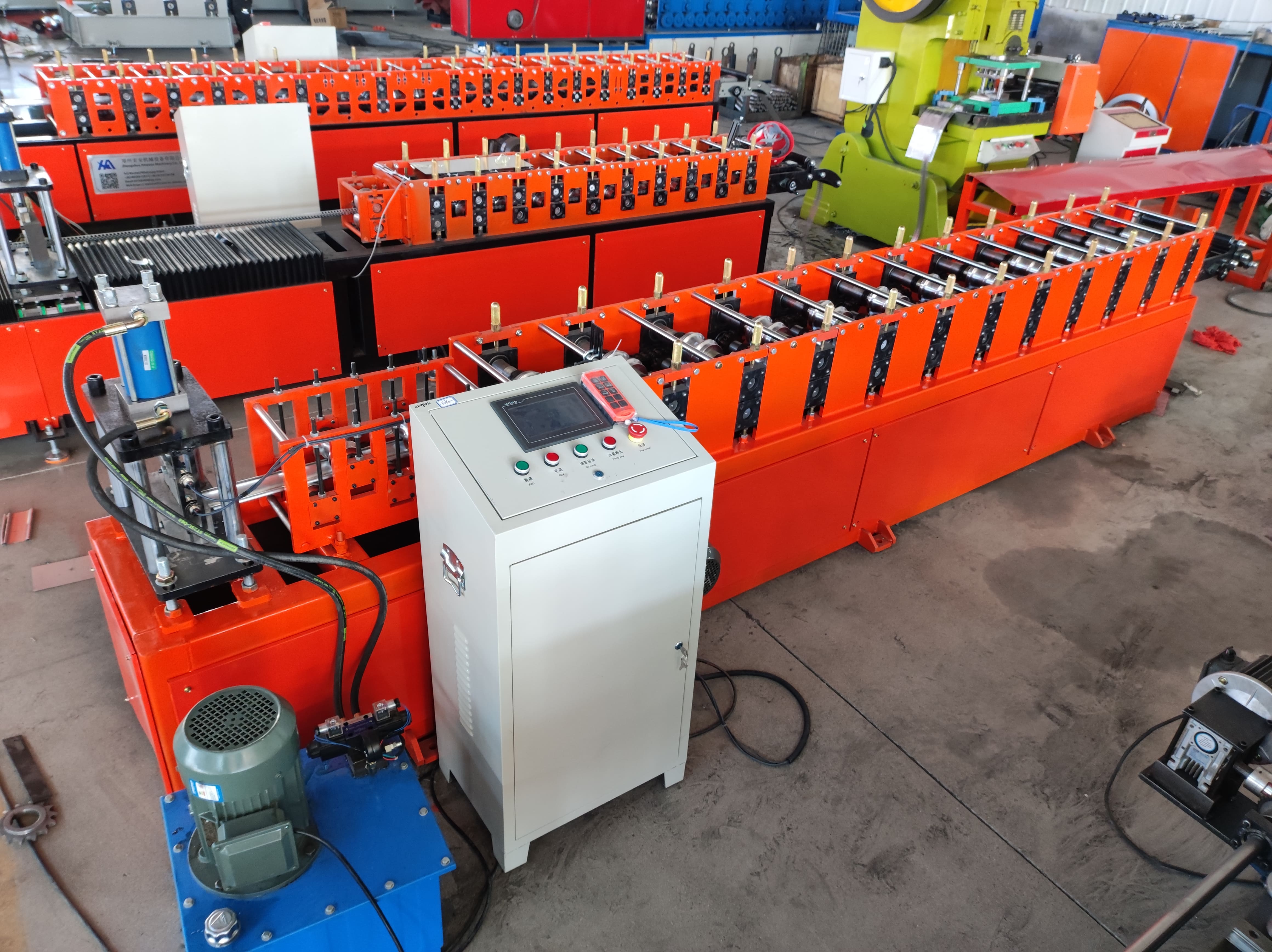

Auto Manufacture Price Steel Shutter Door Profile Slats Roll Forming Machine Cold Metal Guide Rail Frame Roller Making Machine

Roller up door forming machine&Spare parts,More efficient and accurate execution of production orders,High equipment reliability,Little waste of materials and energy,High productivity.

Automatic 0.3-1 mm Galvanized Shutter Door Roll Forming Machine Rolling Shutter Panel Machine Price For Sale

|

Item

|

Specification

|

|

Voltage

|

380V

|

|

Dimension(L*W*H)

|

5900*900*1500

|

|

Weight

|

3500kg

|

|

Rolling thinckness

|

0.8-2MM

|

|

Feeding width

|

124mm

|

|

Raw material

|

GL GI PPGI PPGL

|

|

Roller material

|

45#steel Chrome Plated

|

|

Shaft material

|

45# Steel Outer Diameter: 70mm

|

|

Cutting blade material

|

GCr 12 High Grade Steel

|

|

Main frame

|

350mm/400mm H-Beam

|

|

Control system

|

PLC(imported Brand)

|

|

Cutting type

|

Automatic Hydraulic Cutting

|

|

Decoiler

|

5T Manual Decoiler(with braking function)

|

|

Keywords

|

Slat Shutter Door Forming Machine

|

MOTORIZED UNWINDING — Feeding guide — Roll forming — Leveling — Cutting — Run out product stacker

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

The wheel material is heat treated with bearing steel.

PLC:Delta PLC(or according to customer’s inquirement) Touch Screen:Delta Frequency system:Delta Chinese/English / Russian/Portuguese Or Spanish

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry