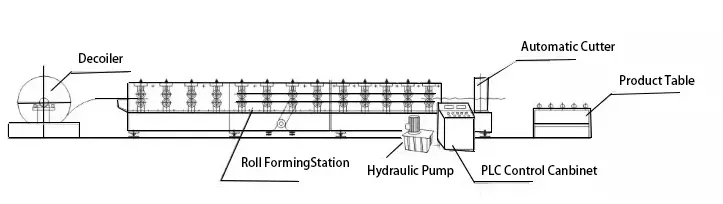

Automatic Custom Design Shelf Storage and Pack Roll Forming / Making Machine

Shelf Rack Series Roll Forming Machine is designed to make many sizes of scaffold plank decking panels in batch and fully automatic.

Automatic Shelving Panel Storage Rack Roll Forming Making Machine Shelf Panel Roll Forming Machine

|

NO.

|

Name

|

QTY

|

Remark

|

|

1

|

5T hydraulic decoiler

|

1 set

|

Max 5T

Max coil:800mm Hydraulic expansion and motorizied decoiling |

|

2

|

Holes Punching & corner cut

|

4 sets

|

We use hydraulic punching machine

Corner cut mould:2 sets ( left and right side can be adjustable manually) Lateral holes punching mould: 1 set( position can be adjustable manually) |

|

3

|

Logo stamping

|

1 set

|

Stamping mould:1 set

|

|

4

|

Roll forming Machine

|

1 set

|

wall panel catilever structure

24 forming stations 15KW motor made in China |

|

5

|

Hydraulic Cutting&bending mould combination

|

1 set

|

Cutting power:7.5kw

Mould material:Cr12.HRC58-62 |

|

6

|

Run-out table

|

2pcs

|

Steel frame with Rollers

|

|

7

|

Electric control panel

|

1 set

|

PLC control system ,Siemens from German brand

Yaskawa inverter from Japan |

|

8

|

Hydraulic system

|

1 set

|

Solenoid is made in China

|

The production line is highly integrated by uncoiling ,leveling,forming,cutting off,punching,receiving and related process. The whole production line is controlled by PCL program .

Details:

|

Suitable Material

|

Galvanized Steel Coil

|

|

Material Width

|

According to Profile Drawing

|

|

Material Thickness

|

0.8-1.2 mm

|

|

Roll forming speed

|

10-15 m/min (Exclude Punching & Cutting Time)

|

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry