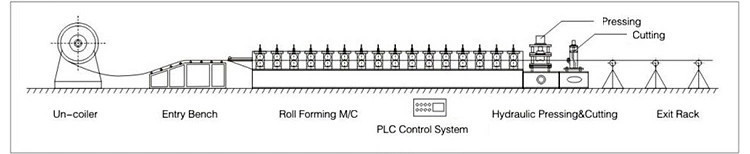

Automatic Wall Panel Color Steel Galvanized Corrugated Iron Glazed Roof Tile Making Machinery

Material metal roof tile trapezoidal roof profile sheet making machine

|

Items

|

model

|

|

Total power

|

5.5 – 7.5kw

|

|

Speed

|

16 – 18m/min

|

|

Material thickness

|

0.15 – 0.7mm (G300-G550)

|

|

Material width

|

914; 1200; 1219; 1450mm

|

|

Transmission system

|

Hydraulic motor

|

|

Cutting system

|

Hydraulic cylinder (front cutting)

|

|

Control system

|

Automatic with PLC, HMI

|

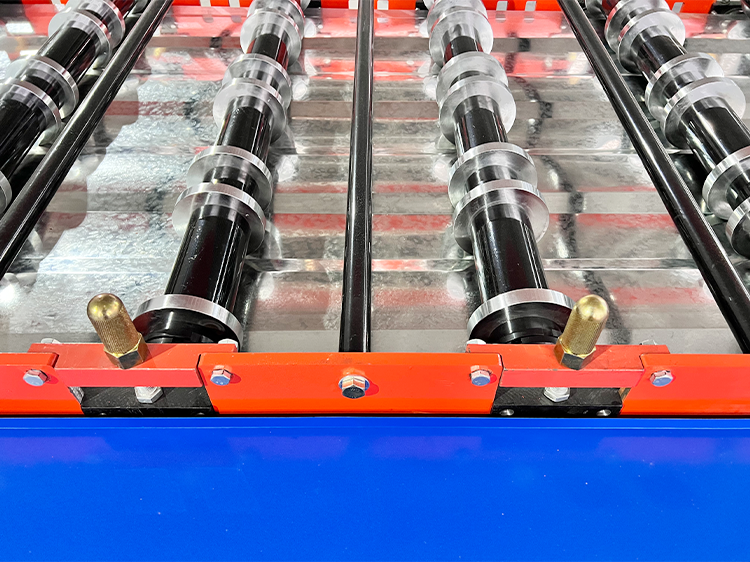

1. This roll forming machine can roll form metal roof panels. After being rolled by this roll forming machine, the surface is very smooth and beautiful without any scratches on the surface.

It is made of 45# steel, through polishing and heat treatment. Processed products are not easy to deform.

Continuously provide power to the equipment, to promote the operation of the equipment.

1. More stable frame for the machine, which we can customized as your prefer one or our standrad one all is ok.

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry