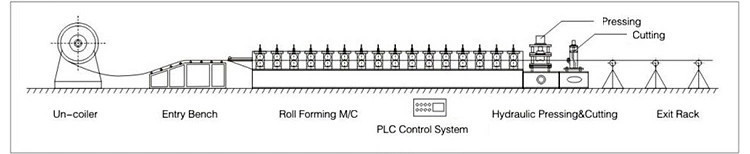

Carriage Top Plate Roll Forming Machine Steel Structural Decking Rolling Forming Machine

Carriage Top Plate Roll Forming Machine:PLC controlled, +/-2mm accuracy. Produces steel floor decks for high-rise buildings. Get a quote!

|

Type of material to be processed:

|

GI/ CR

|

|

Total Connected Power required

|

40 KW

|

|

Max.Width of Coil

|

1300mm

|

|

Max.Width of Coil

|

500mm

|

|

Max.Thickness of Coil

|

2.00 mm(Emboss is Up to 1.6 MM)

|

|

Min.Thickness of Coil

|

0.80mm

|

|

Max.Weight of Coil

|

10000Kg.

|

|

Variable Line Speed

|

0 TO 10mtr/min (without cutting)

|

|

Automation level in performance

|

P.L.C. CONTROLLED LENGTH

|

|

Accuracy Level

|

LENGTH: +/-2 M.M

|

Hydraulic power station: Continuously provide power to the equipment, to promote the operation of the equipment.

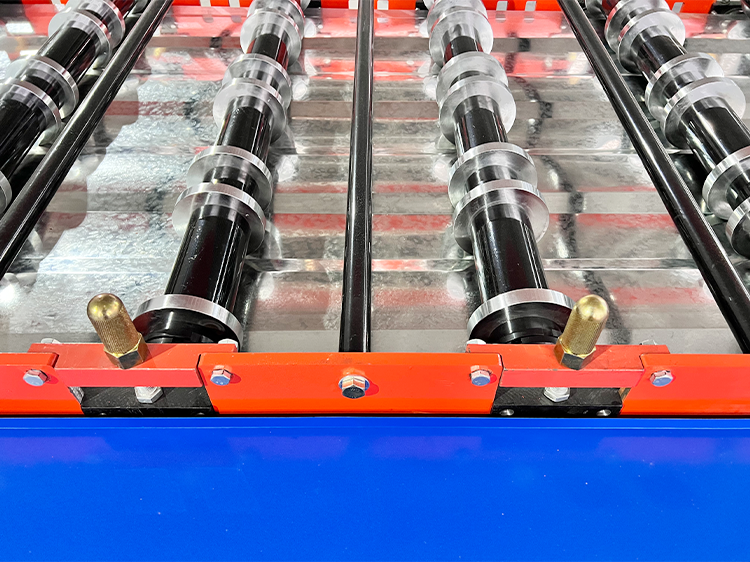

Main rollers: It is made of 45# steel, through polishing and heat treatment. Processed products are not easy to deform.

PLC control system: It can promote the automatic production of machinery, greatly saving human and material resources.

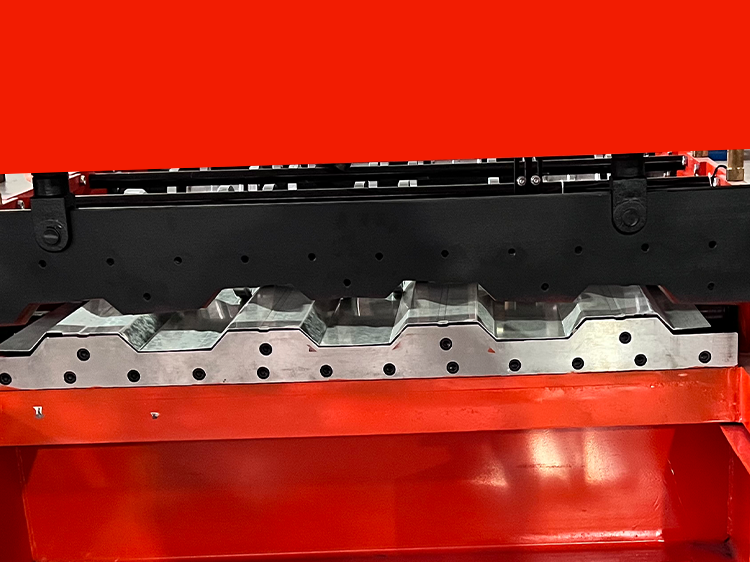

Cutting Knife: Cutting flat raw material very fast, whose cutting raw material is heat-treated for Cr12Mov, and the cutting head is sharper.

This versatile Carriage Top Plate Roll Forming Machine is engineered for a wide range of industrial and commercial construction applications, making it an indispensable tool for modern manufacturing. Its primary function is the high-speed production of durable and precise steel decking profiles. Key applications include:

This machine is capable of forming various profiles, including U-shaped, trapezoidal, and re-entrant profiles, to meet specific project requirements and regional building standards across global markets.

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry