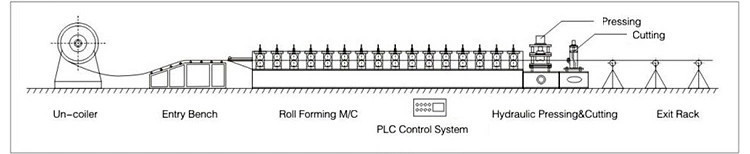

Composite Steel Roof Deck Roll Forming Machine Floor Decking Production Equipment

Composite Steel Roof Deck Roll Forming Machine : Galvanized Sheet Metal 960 Floor Decking Panels Machine. PLC controlled, +/-2mm accuracy. Produces composite steel roof decks for high-rise buildings. Reliable performance.

|

Type of material to be processed:

|

GI/ CR

|

|

Total Connected Power required

|

40 KW

|

|

Max.Width of Coil

|

1300mm

|

|

Max.Width of Coil

|

500mm

|

|

Max.Thickness of Coil

|

2.00 mm(Emboss is Up to 1.6 MM)

|

|

Min.Thickness of Coil

|

0.80mm

|

|

Max.Weight of Coil

|

10000Kg.

|

|

Variable Line Speed

|

0 TO 10mtr/min (without cutting)

|

|

Automation level in performance

|

P.L.C. CONTROLLED LENGTH

|

|

Accuracy Level

|

LENGTH: +/-2 M.M

|

Hydraulic power station: Continuously provide power to the equipment, to promote the operation of the equipment.

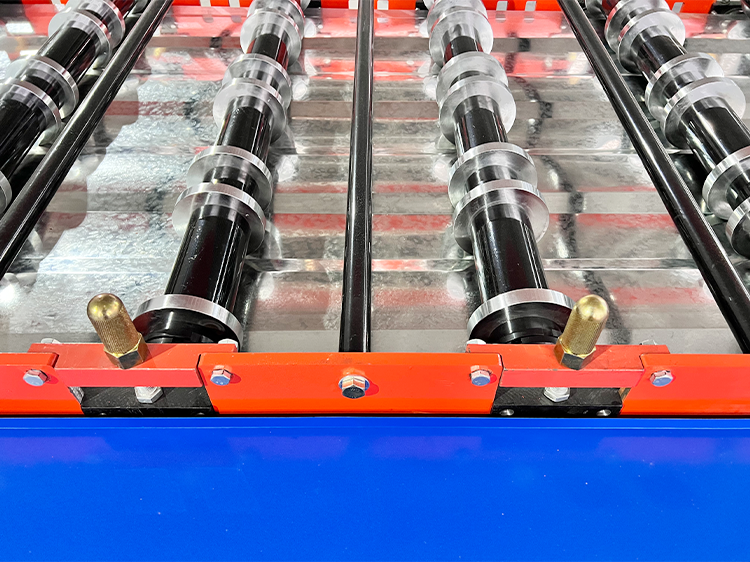

Main rollers: It is made of 45# steel, through polishing and heat treatment. Processed products are not easy to deform.

PLC control system: It can promote the automatic production of machinery, greatly saving human and material resources.

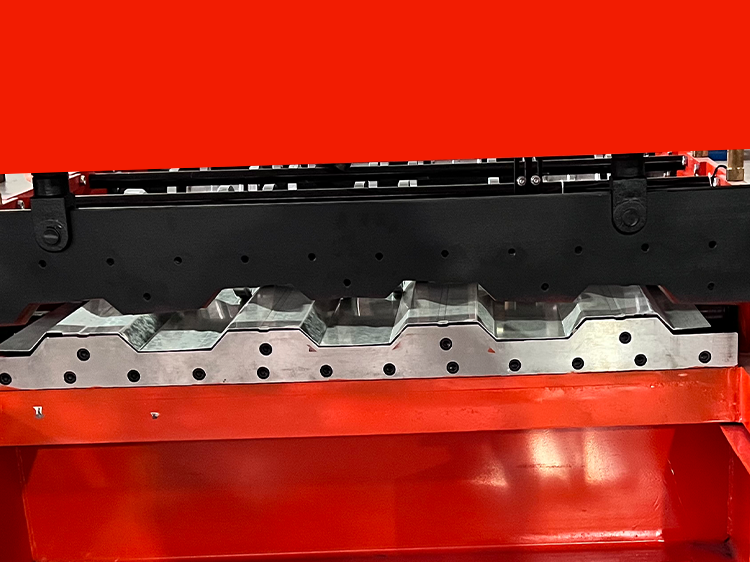

Cutting Knife: Cutting flat raw material very fast, whose cutting raw material is heat-treated for Cr12Mov, and the cutting head is sharper.

The Galvanized Sheet Metal 960 Floor Decking Panels Composite Steel Roof Deck Roll Forming Machine is engineered for diverse applications in modern construction and architectural projects. Its specialized design makes it ideal for:

This versatile machine can be customized to produce various decking profiles meeting international building standards, making it suitable for global construction markets and diverse architectural requirements.

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry