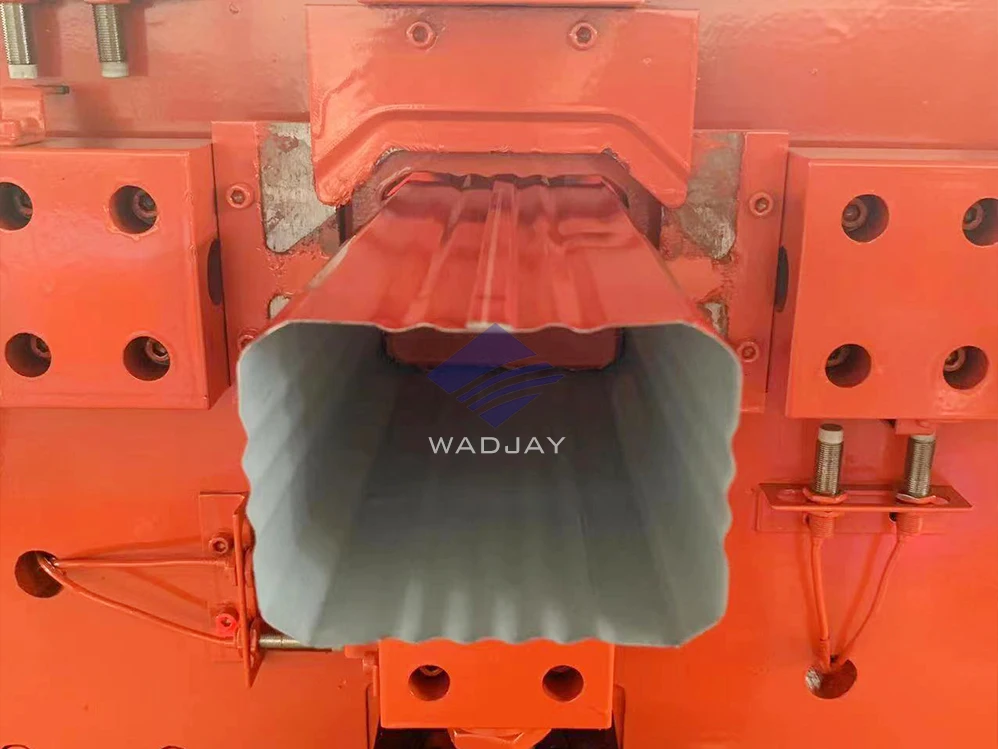

Downspout forming & bending Machine is the complementary equipment for down pipe forming machine. It can make curve for down pipe to meet the requirement of practical engineering.

It is composed of pressing machine and curving die. Pressing machine supplies power and rail for the curving die to curving repose

fully under pressing.