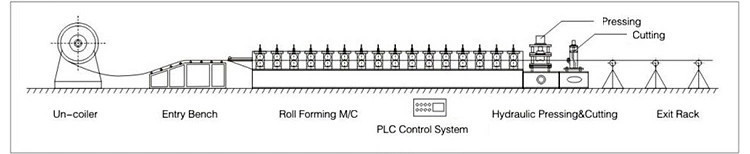

High speed glazed tile roll forming machine metal roof tile production line

The color steel tile forming machine consists of decoiler, sheet guiding unit, plastic film covering unit, roll former, hydraulic pressing unit, hydraulic cutting unit, panel supporter, hydraulic station and AMS control system

|

Suitable to process

|

Color steel plate

|

|

Width of the plate

|

1000mm

|

|

Thickness of the plate

|

0.3-0.7mm

|

|

De-coiler

|

Manual one, can load 5 tons raw material

|

|

Rollers for forming

|

9 rows

|

|

Diameter of the roller

|

70mm

|

|

Rolling material

|

Carbon Steel 45#

|

|

Main motor power

|

4kw

|

|

Productivity

|

0-3m/min

|

|

Cutting method

|

Hydraulic mould cutting

|

|

Material of the cutting blade

|

Cr12

|

|

Hydraulic cutting power

|

3kw

|

|

Processing precision

|

Within 1.00mm

|

|

Control system

|

Delta PLC control

|

|

Side panel of machine

|

14mm

|

|

Main structure of the machine

|

300 H steel

|

|

Weight

|

About 4.0T

|

|

Dimensions

|

7.0*1.5*1.55m

|

|

Voltage

|

380V 50Hz 3phases(changeable as needs)

|

|

Certificate

|

CE/ISO

|

|

Custom

|

According to customer’s requirements

|

1.This roll forming machine can form smooth and beautiful metal roofing sheet without any scratch on surface

1. Suitable for 0.55-0.75mm thickness for Color steel sheet with yield strength max.235Mpa;

2. Line speed: 5m/min for 6000mm panel length and 380mm Punching steps;

3. 21 roller stands;

4. AC380/AC480V, 50Hz/60Hz,30Kw;

5. Profile drawing:

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry