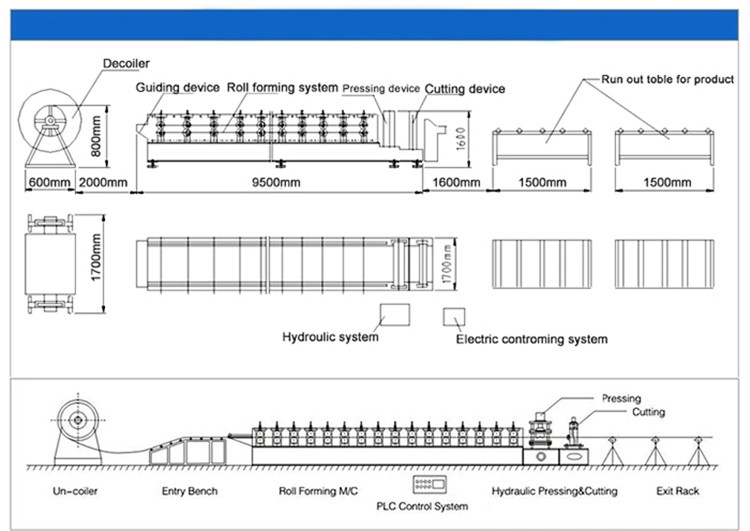

Roof Panel Former IBR Roof Roll Forming Machine Single Layer Roof Panel Former

Roof Panel Former IBR Roof Roll Forming Machine: 25m/min speed, ±0.5mm precision. Forms single-layer panels from 0.3-0.8mm steel/aluminum. PLC-controlled. ISO certified for industrial roofing.contact us.

|

Suitable material

|

color steel sheet, galvanized steel sheet, aluminium sheet

|

|

Material width

|

1250mm or as your required

|

|

Material thickness

|

0.3-0.8 or as your required

|

|

Working speed

|

8-12m/min, can be 20-25m/min

|

|

Main motor power

|

5.5kw with cycloidal with reducer

|

|

Hydraulic pump power

|

4kw

|

|

Electrical control system

|

PLC control system with inverter

|

|

Shaft diameter

|

75mm

|

|

Roller station

|

15 rows, depend on your panel profile drawing

|

|

Roller

|

high grade 45# steel, hard chrome plating

|

|

Working time

|

24 hours

|

|

workers

|

1-2 only

|

|

Cutting head material

|

Cr 12 mould steel with quenched treatment

|

|

Voltage

|

380V 3Phase 50Hz or as your required

|

1. This roll forming machine can roll form metal roofing sheet. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface.

2. Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

3. Fully Automatic Control System with PLC.

4. Easy operation: Key in the length and quantity on the control panel.

5. We also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

We are professional manufacturers, product quality and price are guaranteed

Contact Info

Featured Categories

Social

Copyright © 2023 Henan WadJay Machinery Co., Ltd. All rights reserved

By search to tind machine what are you what?

Send inquiry