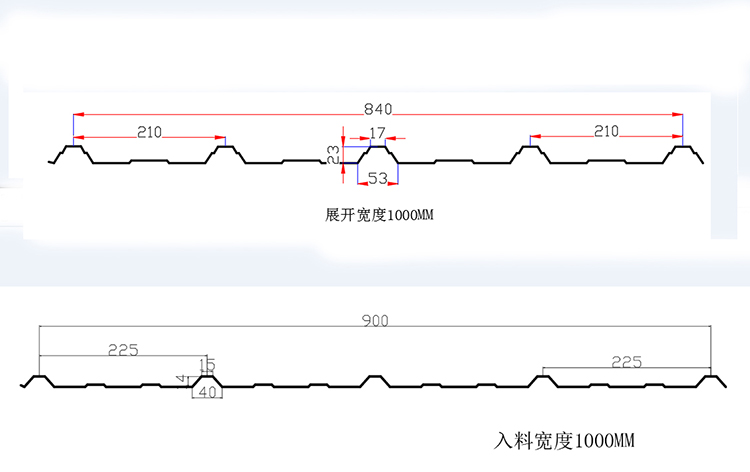

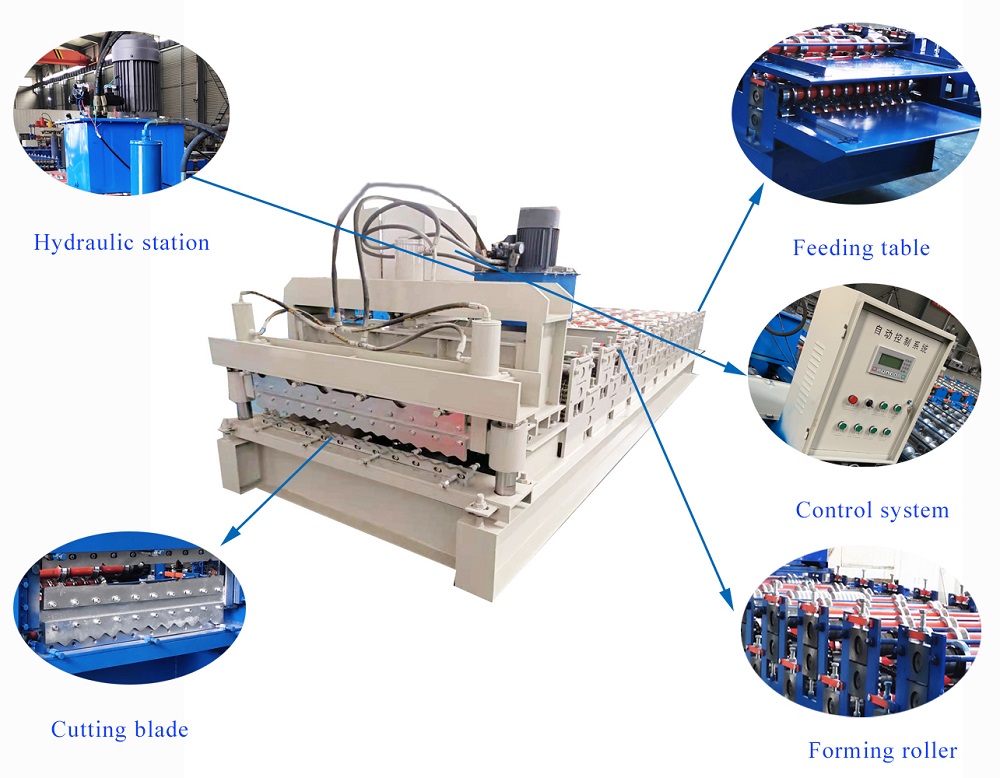

Roof Sheet Double Layer Forming Machine,it is our company most popular products in building materials machine.For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine,

trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile

panel roll forming machine.